We demand a lot from our utility trailers and work trailer, and often use them to the max. Additionally, we also lack the time and neglect the routine maintenance required to keep our trailers safely on the road and, without fail, they break when we need them the most. At John’s Spring and Suspension we specialize in utility and work trailer repair, including flat bead trailers, horse trailers, and equipment trailers. We have all the required tooling, parts, and experience to get your trailers back on the road quickly. We are experts in suspension and repairing anything that is chassis related.

Trailer Suspension Upgrade and Repair

You know you need to have your suspension repaired or replaced when you notice that your trailer is sagging or you have a broken spring. A common symptom of this is that your tires will rub on the underside of the fender well or your axles are misaligned. There are two main reasons we see trailers that need suspension repair or replacement:

You know you need to have your suspension repaired or replaced when you notice that your trailer is sagging or you have a broken spring. A common symptom of this is that your tires will rub on the underside of the fender well or your axles are misaligned. There are two main reasons we see trailers that need suspension repair or replacement:

- Excess weight requiring spring replacement or a heavy duty upgrade to increase capacity and/or trailer ride quality

- Off road driving conditions may cause trailer springs to fail prematurely

We can upgrade your spring capacity on a utility trailer to handle additional weight. Often stock trailers have the lowest weight rated springs compatible with the trailer and do not hold up to normal abuse. If you already pushed that weight limit and find yourself with a broken spring, we can help. Or if you know you need your utility trailer to work harder for you, we can install heavy duty springs to increase its longevity and capacity. We will work with you to determine the best spring for your application and requirements. Expect more from your trailers, John’s Spring can help.

Trailer springs can start to flatten with time or use to the point where the backend of your trailer starts to visibly sag. This usually results in the tires rubbing the underside of the fender or wheel well as well as can lead to the back of the trailer dragging on the ground when maneuvering into driveways or other angled areas. This makes it hard or even dangerous to back into some spots or go on certain roads. Replacing your trailer suspension with heavy duty springs allows you to have greater ground clearance and a better level on your trailer.

A trailer spring almost always breaks close to the eye of the spring. If it breaks anywhere other than the eye of the spring, it is usually an indication of loose U-bolts. We custom make U bolts on-site at our shop. Usually, repairing a broken trailer spring is more cost effective to replace the entire spring than to replace just the broken leaf. However, we can add leaves or make a “military wrap” around the main leaf to offer additional support to the spring. Bring your trailer by the shop and have a free estimate and discuss different options for your trailer suspension.

At John’s Spring and Suspension, we carry the full line of repair parts for your suspension, from springs and shackles, to equalizers and hardware. Since we have all the parts in stock, our turn-around times are usually much faster than other trailer repair shops in the Reno area.

We pride ourselves on fixing the issue completely using quality parts. This provides our customers with the best possible results and customer service.

Trailer Brake Repair

Load and weight may cause uneven wear on your braking system. For heavy to moderate trailer use, you should have your trailer brakes looked at proactively at least once a year. Some obvious signs that your brakes are in need of replacement include noise, pulling, pulsing and pedal depression during braking. In extreme situations of brake failure or brake component failures, your wheels can lock up while traveling, causing severe tire damage.

We can service suspension, bearings and brakes all in one appointment. When we are servicing trailer suspension, we take the wheels off and check the bearings and brakes to ensure all parts of the trailer are inspected. If there is an issue with the brakes, we have the parts and equipment to repair or replace them. We service both manual and self-adjusting electric trailer brakes. With electric brakes, we replace the whole assembly so that the entire system is brand new. This maximizes the life of the entire system and so that you do not have to worry about small components or used components failing.

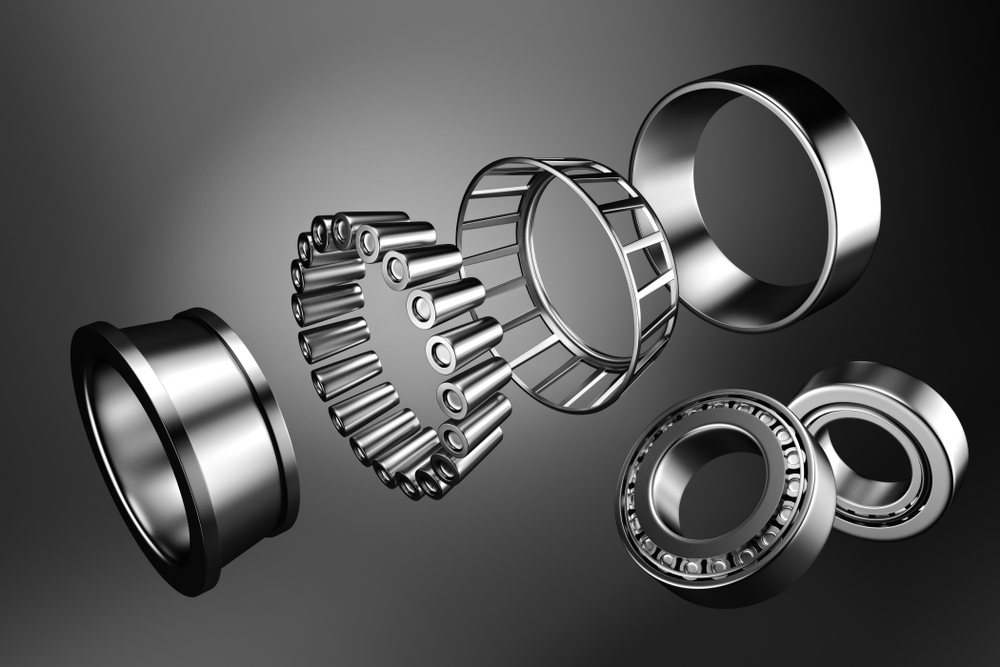

Trailer Wheel Bearing Re-Packing

Periodic wheel bearing maintenance is necessary to keep them from overheating and failing. To avoid a wheel bearing failure, you should regularly repack your wheel bearings. For heavy use utility trailers, this should be done once a year.

We will repack the wheel bearings by pulling out the bearing, removing old grease, adding fresh grease and installing all new seals. We offer complementary bearing inspection when you come in for spring repair or replacement. It is a pretty good bet that if you need new or upgraded springs, your wheel bearings also need some attention. It is our goal to ensure full functionality of your trailer’s chassis when you pull out of our shop. We know you’re ready to get back to work, rest assured, your trailer will be as well after leaving John’s Spring and Suspension.

Welding and Minor Trailer Repairs

When your trailer is at John’s Spring for larger suspension or brake repairs, we can also handle welding and minor repairs so you only have to bring your trailer in once, to one shop. These repairs can be in cases of wear and tear, damage, or increased security for the components of your trailer, such as batteries or propane tanks.

We can handle bracketry repair for things like tie downs, landing legs, hitch components, and small electrical, such as brake light wiring. If you have old welds that are cracked, we can repair those and also secure things that may be loosened or coming off.

In addition to utility welding for things that are broken or worn, we can also do cosmetic welding for things like battery cages, propane tank covers, and spare tire carriers.