If you drive across the rugged terrain of the western U.S., knowing how to measure leaf springs is a must for keeping your rig safe and road-worthy. Whether your truck or trailer is creeping and sagging or you’re preparing to replace worn suspension parts, accurate measurement ensures you order the correct component and avoid costly errors.

In this guide, we’ll walk you through everything from fundamentals to best practices so you can confidently tackle this task.

Understanding Truck and Trailer Leaf Springs

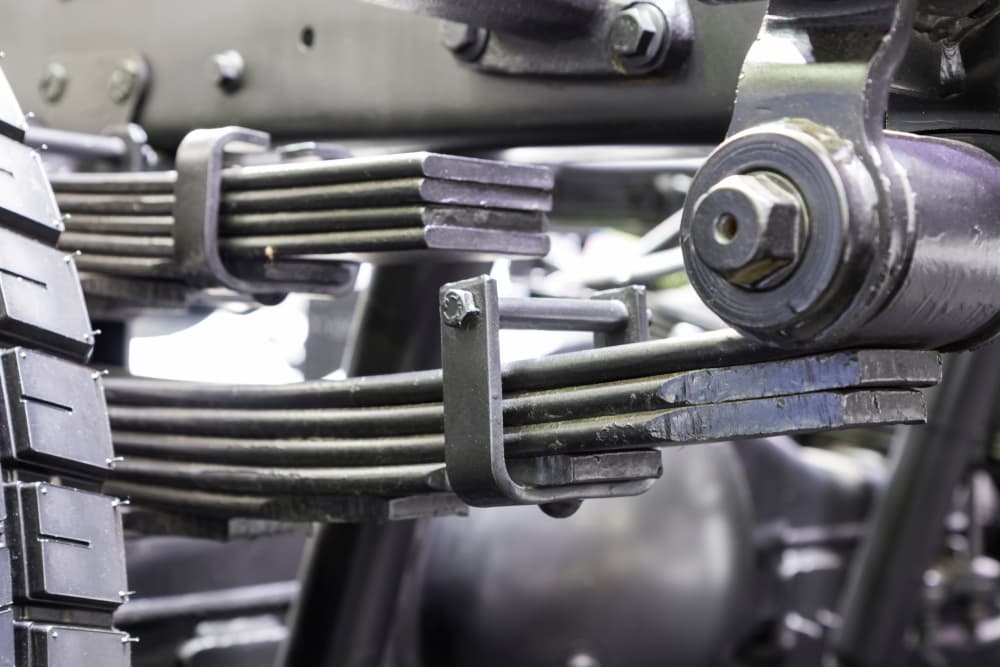

Leaf springs are a series of metal “leaves” stacked and arched to absorb shock, support weight, and help maintain stability. In trucks, a truck leaf spring assembly may consist of multiple leaves of varying widths and lengths, designed to support heavy cargo. On trailers, a trailer spring is often simpler, with fewer leaves, but still critical to ride comfort and load distribution.

Because trucks and trailers impose different demands, the design, curvature, and load rating of the leaf spring can vary substantially. Some springs are re-arched (re-arched) or modified (add-a-leaf) to adjust ride height, but regardless of such tweaks, the baseline dimensions must be accurate. Mis-sized suspension parts can lead to imbalance, uneven tire wear, or even frame damage.

Tools You’ll Need to Measure Leaf Springs Accurately

Precision in measuring comes down to using the right tools and having a stable work setup. Before you begin:

- Measuring tape (preferably steel) with at least 6–10 feet in length

- A straightedge or rigid bar to ensure your measurement is flat

- Marker, chalk, or scribe to mark endpoints or centers

- Safety gear (gloves, eye protection) — springs and edges can be sharp

- Jack and jack stands, or ramps, to lift the truck/trailer if your springs are not easily accessible

- Level surface — park on firm, level concrete to reduce measurement error

With these in hand, you’ll reduce guesswork and better capture true leaf spring length for your replacement ordering.

Step-by-Step Process: How to Measure Leaf Spring Length

Follow these steps carefully:

- Park on level ground. Ensure the vehicle is unloaded or as close to its typical load as possible. This helps the spring settle under normal weight.

- Locate the spring ends. Identify the eyes or mounting points of the leaf spring (often the front and rear hangers or shackle points).

- Mark endpoints. Use chalk or a marker to identify exactly where the spring contacts the mounting brackets or hanger eyes.

- Run the measuring tape. With the spring relaxed (no extra upward or downward load), measure from the center of one mounting point to the center of the other. This gives you the eye-to-eye length.

- Measure the arch or camber. Place a straightedge across the spring ends, then measure the distance from that straightedge to the center (this is the arch or rise).

- Measure the width and the number of leaves. Record the full width of the leaf pack and count how many individual leaves comprise it.

- Record all dimensions. Write everything down carefully: eye-to-eye length, arch, width, number of leaves, and any asymmetries (left vs. right side).

These measurements together are crucial, not just the leaf spring length alone. Many replacement suppliers will ask for all these values to ensure a perfect match.

Tips for Ensuring Accurate Measurements and Selecting Replacements

- Double-check both sides: Sometimes left and right leaf spring packs differ slightly due to wear, previous repairs, or asymmetrical loading.

- Measure under load: If possible, measure when the vehicle carries its typical load to account for sag.

- Don’t stretch or compress the spring while measuring. Let it rest naturally.

- Consult manufacturer specs: OEM or aftermarket suppliers often provide spec sheets where your measurements should fall.

- Match load ratings: Even if dimensions match, picking a spring with insufficient load capacity can be disastrous.

- Consider re-arching or add-a-leaf options: John’s Spring, for instance, offers re-arching, add-a-leaf, and full replacement services to restore proper ride height and performance. John’s Spring and Suspension

- Replace in pairs: Always replace both left and right springs together to maintain balanced suspension behavior.

By following these tips, you lower the chance of ordering the wrong part or ending up with a suboptimal ride.

Professional Accuracy Matters

When it comes to heavy trucks and trailers, suspension components like leaf springs are not the place to gamble. Accurately measuring and selecting the right part ensures longevity, safety, and better performance. If at any point you feel unsure or require custom shaping—such as matching spring curvature or re-arching—draw on expert services. For example, John’s Spring in Reno offers leaf spring repair, full replacement, re-arching, and custom spring fabrication for trucks and trailer suspension systems. John’s Spring and Suspension

Whether you’re maintaining a heavy Class 8 rig or a smaller utility trailer, knowing how to measure leaf springs gives you confidence and control when selecting replacements. Use this guide as your reference, take careful measurements, and trust John’s Springs and Suspensions when precision matters most. Our team is here to help when you need us the most — from expert advice to professional leaf spring repair and replacement services that keep your truck or trailer safe and road-ready.